The History of Tension Fabric Structure Buildings

I am going to present a few articles about the history and facts about Tension Fabric Structures.

This first one – Tension Fabric: Wave of the Future is about large scale Tension Fabric Structures in Architecture. It is certainly a very related field although the stakes are higher, if you will. Shelter being of utmost importance means weight loads on wind, snow etc. The large scale makes the materials different, however as I already stated we in the ultra-light weight tension fabric structures are a kissing cousin. We learn and grow from each other. Our stretch fabric shapes relate exactly the the design flexibility of the medium, as tension fabric has unique physical properties due to its basic structure that makes it an incredibly versatile building material.

Fabric Structures have been a part of man’s landscape…well…forever! For example tents and unique tensioned fabric structures ranging from the black tents of the Bedouins, Berbers, Moors, and Kurds to the highly evolved American tipi of the Native Americans. In the 1950’s a realization that these tension fabric concepts could relate to architecture. Take a read of this “illumin” article and it will inform you of large scale weather-proof tension fabric structures!

Tension Fabric: Waves of the Future

(Written by: Mark Weaver for USC University of Southern California)

Introduction

History of Tension Fabric Structures

Tension Fabric Internal Structure

Fabrication of Base Fabric

There are three main types of tension fabric used in architectural applications today: PVC coated polyester, silicon coated fiberglass, and Teflon coated fiberglass. PVC coated polyester is the cheapest and easiest to manage of the three but also has the shortest life span. Teflon and silicon coated fiberglass are more durable, but are also more expensive [4]. However, the basic structure of the material is similar for all three. The bottom layer of the tension fabric is a base fabric, usually made out of polyester or fiberglass. This fabric is created with fibers that run perpendicular, or in the warp and welt directions, and are weaved in and out of each other. The base fabric is extremely important as it dictates a number of the final fabric properties including stress and strain properties (how much force the fabric can take and how long it can stretch before failure) [3]. The end result is an incredibly strong material: fiberglass fiber has a tensile strength of 3200 Mega-Pascal (MPa) [5]. To put this number in perspective, structural steel only has a tensile strength of roughly 250 MPa. In order to create a stronger final fabric, one could use a bigger denier (size) of fiber or create a fabric with more fibers per square inch [3]. In addition to the incredible strength of the base fabrics, they are also relatively translucent and reflective. For example, Teflon coated fiberglass has a reflectivity of seventy percent [5].

The Exterior Coating

Important Application Criteria

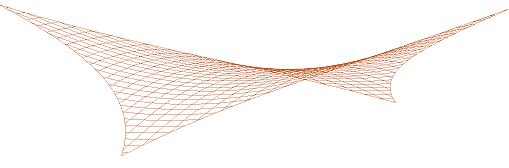

Essential Pre-stressing

Form follows Function

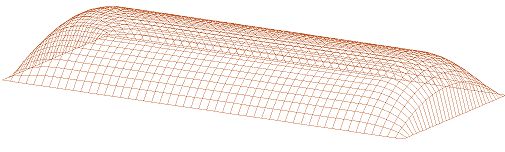

On the other hand, synclastic shapes are characterized by having the radii of the principal curvatures on the same side of the fabric (Fig. 2). In order to counteract external forces, pressure from within is necessary. This is why synclastic shapes are associated with air inflated structures, as the difference of pressure created by air pumped into the building is able to counteract external forces in the form of wind or snow [7].

Implications of Fabric Tension Structures

Exterior Form and Aesthetics

The Interior

Environmental Observations

Conclusion

References

-

- [1] Red Sky Shelters. “The History of Tensile Architecture.” Red Sky Shelters. http://www.redskyshelters.com/tensilehistory.html.

- [2] “Millennium Dome.” Midas User. http://www.midasuser.com/info/land/read.asp?index_id=4&pg=1&so=1&sk.

- [3] Seaman Corporation. “Utilization of Vinyl Coated Polyester Fabrics for Architectural Applications.” Seaman Corporation. http://www.architecturalfabrics.com/whitepaper.html.

- [4] N. Browne. “CPD.” Fabric Architecture and Signature Structures. http://www.fabricarchitecture.co.uk/cpd.htm.

- [5] U. Gandhi. Design and Construction of Tension Membrane Structures. [2003]. http://homepages.cae.wisc.edu/~ukgandhi/documents/tensile%20structures_paper.pdf.

- [6] Taiyo Birdair Corporation. “Custom Tension Structures.” Taiyo Birdair Corporation. http://www.taiyobirdair.com/index.php?submenu=ProdStructures &src=gendocs&link=Custom&category=Produc tsServices&FREEDOMSITE=dc5026d72c982a0934f3e397a9e447d.

- [7] Intents. “About Membranes” Technical. Intents. http://www.intents.be/default2.asp.

- [8] “Georgia Dome.” Midas User. http://www.midasuser.com/info/land/read.asp?index_id=13.

- [9] L. Babetski, E.Karp. H. Terminal, K. A. Aziz International Airport Jeddah Saudi Arabia.http://darkwing.uoregon.edu/~struct/resources/case_st udies/case_studies_suspension/haj_terminal/haj_terminal.html.

1 Comment

Comments are closed.